Approved by the

Decree of the Federal

Environmental, Industrial

and Nuclear Supervision

Service dated November 14, 2018. No. 554

FEDERAL RULES AND REGULATIONS

IN THE FIELD OF USE OF ATOMIC ENERGY "WELDING AND

SURFACING OF EQUIPMENT AND PIPELINES OF NUCLEAR

POWER INSTALLATIONS"

(NP-104-18)

I. Purpose and scope of application

1. These Federal Rules and regulations in the Field of Nuclear Energy Use "Welding and Surfacing of Equipment and Pipelines of Nuclear Power Installations" (NP-104-18) " (hereinafter referred to as the Rules) were developed in compliance with Federal Law dated November 21, 1995. No.170-FZ "On atomic energy use", Provisions for development and approval of federal rules and regulations in the field of atomic energy use approved by Decree of the Government of the Russian Federation No. 1511 dated 1 December 1997 N 1511 (Code of legislation of the Russian Federation, 1997, N 49, art. 5600; 2012, N51, art. 7203).

2. These Rules establish requirements for the manufacture, installation and repair of equipment and pipelines of nuclear power installations:

a) to perform welding and surfacing, including welding materials, welding equipment, preparation and assembly for welding, types of welded joints, heat treatment of welded joints and surfaced parts;

b) to control of the quality of welding and surfacing materials;

c) to elimination of defects and control over the same.

Requirements for welding and surfacing should be taken into account in the development of engineering (design) documentation.

3. These Rules apply to the performance of welding and surfacing of parts and assembly units:

a) the equipment and pipelines subject to federal rules and regulations in the field of atomic energy use "Rules of the design and safe operation of the equipment and pipelines of nuclear power installations" (NP-089-15) approved by the order of the Federal Service for Environmental, Industrial and Nuclear Supervision dated December 16, 2015 No. 521 (registered by the Ministry of Justice of Russia on February 9, 2015, registration No. 41010) (hereinafter referred to as NP-089-15);

b) the equipment and pipelines working under excessive or vacuum pressure and referred to elements of the third class of safety not subject to NP-089-15;

c) supports and hangers of equipment and pipelines specified in subparagraphs "a" and "b" of this paragraph;

d) internals of water-water reactors and reactors on fast neutrons;

e) metalworks of fuel holding pools, refueling ponds, spent fuel pools of nuclear power installations.

4. These Rules establish requirements to performance of welding of parts and assembly units of equipment and pipelines made of the following materials:

a) of steel grades St3sp5, 10, 15, 20, 15L, 20L, 25L, 20K, 22K, 15GS, 16GS, 20GSL, 09G2S, 09G2SА-A, 10KhSND, 10KhN1М, 16GNMA, 12MKh, 12KhM, 15KhM, 20KhM, 20KhМА, 10Kh2M, 12Kh1MF, 15Kh1M1F, 10GN2MFA, 10GN2MFA-A, 12Kh2MFA, 12Kh2MFA-AD, 15Kh2MFA, 15Kh2MFA mod. A, 15Kh2MFA-A, 15Kh2MFA-A mod. A, 15X2MFA-A mod. B, 18Kh2MFA, 18Kh2MF A-A, 15Kh2NMFA, 15Kh2NMFA-A, 15Kh2NMFA class 1, 15Kh2NM1FA, 15Kh2NM1FA-A, 15Kh3NMFA, 15Kh3NMFA-A (these will be hereinafter referred to as the steels of pearlitic class, steel grades St3sp5, 10, 15, 20, 15L, 20K, 25K, 20K, 22K hereinafter referred to as the carbon steel grades 15GS, 16GS, 20GSL, 09G2S, 09G2SA-A - silico-manganese, and other steel grades - alloyed ones);

b) of steel grades 08Kh13, 10Kh9MFB, 05Kh12N2М, 06Kh12N3D, 06Kh12N3DL, 08Kh14MF, 07Kh16N4B, 07Kh12NFMB (these will be hereinafter referred to as high-chromium ones);

c) of steel grades 08Kh18N9, 09Kh18N9, 10Kh18N9, 12Kh18N9, 08Kh18N10, 03Kh16N9М2, 08Kh16N11М3, 12Kh18N12M3TL, 12Kh18N9T, 12Kh18N9TL, 06Kh18N10T, 08Kh18N10T, 12Kh18N10T, 08Kh18N12T, 12Kh18N12Т, 10Kh17N13M2T, 10Kh17N13M3T, 03Kh22N5АМ3, 03Kh25N7АМ4 (these will be hereinafter referred to as austenitic steels);

d) of iron nickel alloys 03Kh21N32М3B, KhN35VT, KhN78T;

e) of pearlitic class steels with parts made of high-chromium steels, austenitic steels and iron-nickel alloys;

f) of high-chromium steels with austenitic steel parts;

g) of titanium and its alloys of grades VT1-00, VT1-0, PT-1M, PT-3V, PT-7M, 3M, 5V, 5 VL, TL3, TL5, 19;

h) of aluminum alloys of grades ADOO, ADO, AD1, AD, AV, SAV1, AMg2, AMg3.

Further, the welding of parts made of materials listed in subparagraphs "e" and "f" of this paragraph is referred to as the welding of parts made of steels of different structural classes.

These Rules also establish requirements for the performance of welding of parts of two-layer steels with the base layer of carbon or alloy steel, and a plating layer of steel 08Kh18N10T, or 08Kh19N10G2B, or with anti-corrosion cladding made with, among others, Sv-08Kh19N10G2B Sv-04Kh20N10G2B, Sv-03Kh22N11G2B, Sv-03Kh24N13G2B.

5. These Rules establish requirements to performance of surfacing of details from the materials listed in subparagraphs "a" -"d", "g" of paragraph 4 of these Rules.

6. Welding and surfacing must be carried out in accordance with the process documentation developed taking into account the requirements of these Rules and engineering documentation.

7. Process documentation for welding and surfacing of parts and assembly units of equipment and pipelines manufactured (mounted) before the entry into force of these Rules or being in the manufacture (installation) at the time of their entry into force, shall not be subject to revision.

8. Process documentation for the repair of welded joints and overlaid surfaces of equipment and pipelines repaired prior to the entry into force of these Rules or being under repair at the time of entry into force of these Rules shall not be subject to revision.

9. Welding and surfacing of equipment and pipelines should be performed by personnel who have passed theoretical and practical training and is allowed to work independently in the manner prescribed by the organization performing these works.

10. The terms and definitions used are given in Appendix No. 1 to these Rules.

II. Welding and surfacing materials

11. Information on the materials applied for performance of welding (surfacing) of parts and assembly units of the equipment and pipelines are given in Appendix N 2 to these Rules.

At welding (surfacing), materials must be used admitted for use subsequent to requirements of standardization documents included into the Consolidated List of standardization documents in the field of atomic energy use, which shall be used without fail (hereinafter referred to as the Consolidated List) as stipulated in the Regulations on standardization for the products (works, services) subject to requirements related to safety assurance in the area of atomic energy use as well as processes and other standardization objects associated with such products, approved by Decree of the Government of the Russian Federation dated July 12, 2016 No. 669 (Collected legislation of the Russian Federation, 2016, No. 29, Art. 4839).

12. For the use of welding (surfacing) materials not included in the Consolidated List, a conformity assessment in the form of certification tests of the material must be carried out. Requirements to the certifying tests substantiating the application of a new welding (surfacing) material are given in Appendix N 3 to these Rules.

The welding (surfacing) material should be used after the inclusion of the material standardization document in the Consolidated List.

III. Welding equipment

13. To perform welding and surfacing, equipment and measuring instruments must be used ensuring compliance with the requirements of these Rules.

14. The applied equipment shall provide observance in permissible limits of the parameters of the modes of welding (surfacing) established in the process documentation.

15. Equipment for argon arc welding with a non-consumable electrode and plasma surfacing with powder materials should be furnished with devices for smooth arc quenching.

16. Metrological support of measuring instruments used in welding and surfacing shall be carried out in accordance with the legislation on ensuring the uniformity of measurements.

IV. Control of the quality of welding and surfacing materials

General requirements

17. All the batches of welding and surfacing materials intended for welding and surfacing of equipment and pipelines are subject to control.

18. The control of the quality of welding and surfacing materials includes:

a) check of cover documentation;

b) check of packaging and the condition of welding and surfacing materials;

c) control of the metal of seam and the metal of surfacing.

19. Control of quality of welding and surfacing materials shall be exercised by the organization using these materials at welding (surfacing) of the equipment and pipelines.

20. Control of quality of each batch of welding and surfacing materials should be carried out prior to their use.

21. With the organization-manufacturer of the equipment and (or) assembly units of pipelines using welding (surfacing) materials of their own production, it is allowed to have combination of quality control of welding and surfacing materials with acceptance control of specific batches of welding and surfacing materials.

Check of cover documents

22. Each batch of welding and surfacing materials should be checked:

(a) for availability of a certificate (or label for gas cylinders) with the verification of the completeness of the data contained therein and their compliance with the requirements of the standardisation documents for welding and surfacing materials included in the Consolidated List;

b) for each packaging place having marking indicating the brand, gauge and batch number of the material.

23. The results of the inspection of materials are documented by log entries. In addition to the welding material inspection log, a log of baking of coated electrodes and welding fluxes must be kept to ensure that they can be used after baking.

24. The composition and content of the reporting documentation for the control of materials used for welding and surfacing works during repairs of equipment and pipelines are determined by the operating organization.

Check of packaging and the condition of welding

(surfacing) materials;

22. Each batch of welding (surfacing) materials should be checked:

a) for absence of damage of package and (or) materials as such;

b) on compliance with the certificate data and requirements of the documents on standardization included in the Consolidated List.

26. At the check of welding (surfacing) materials, the following shall be controlled:

a) each batch of the covered electrodes - on compliance of the nominal sizes of electrodes with the data of the certificate and the condition of their coverage with requirements of the documents on standardization included in the Consolidated List;

b) each batch of welding (surfacing) wire and tape - for compliance of the nominal sizes and type of the surface with the data of the certificate and the condition of the surface with requirements of the documents on standardization included in the Consolidated List, as well as for existence of marking from two sides of the coil of welding wire and tape;

c) each batch of flux - for compliance of color, uniformity and granulometric structure with requirements of the documents on standardization included in the Consolidated List.

27. The decision on further full or partial use of welding (surfacing) materials in case of damage of packaging and (or) materials shall be made by the organization applying the specified materials.

28. Each batch of coated electrodes and fluxes before use should be checked for compliance of moisture content in the coating of electrodes and flux moisture with requirements of documents on standardization of controlled welding materials included in the Consolidated List, or for compliance with the conditions and terms of storage after the next baking.

29. When using a batch of coated electrodes or flux in parts, the moisture content of the coating and the moisture content of the flux must be checked separately for each part of the batch to be used.

Repeated baking should be carried out in cases where the moisture content in the coating of the electrodes or the moisture content of the flux exceeds the norms established by the standardization documents included in the Consolidated List, as well as in case of violation of the conditions and terms of storage after baking.

30. The requirements to storage of welding (surfacing) materials are presented in Appendix 4 to these Rules.

Control of the metal of seam and the metal of surfacing

31. The following shall be subject to control:

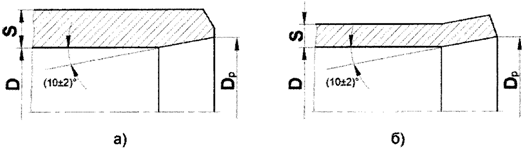

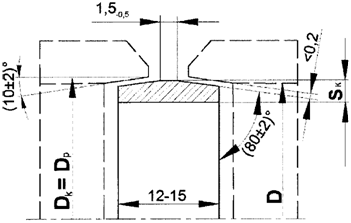

a) each melt of welding wire and tape;

b) each batch of electrodes, fluxes and powder materials.

32. For performance of welding (surfacing) materials, reference weld seams (overlays) shall be made.

33. Reference weld seams are subject to total visual, measuring and radiographic or visual, measuring and ultrasonic inspection.

34. Reference overlays are subject to total visual and capillary or visual and magnetic powder (except for surfacing made of austenitic materials) control, and in cases provided for by the process documentation, ultrasonic and (or) radiographic control, as well.

35. Reference weld seams and reference overlays are subject to nondestructive testing (in the initial state after welding and (or) after heat treatment, if it is required), upon the positive results of which destructive testing is carried out.

If the total length of the defective areas detected during nondestructive testing does not exceed 5% of the length of the reference weld seam or the reference overlay, the destructive testing shall be carried out from samples not cut from the defective areas.

36. The results of non-destructive and destructive testing of reference weld seams and reference overlays must meet the requirements of federal rules and regulations in the field of atomic energy use regulating the control of metal equipment and pipelines of nuclear power installations in the manufacture and installation.

37. The assessment of results of nondestructive testing should be performed depending on categories of welded joints which must meet higher requirements for assurance of safety.

Categories of welded joints are established in engineering documentation according to requirements of federal rules and regulations in the field of atomic energy use regulating control of metal of the equipment and pipelines of nuclear power installations at production and installation.

If the category of welded joints is not established, the nondestructive testing shall be evaluated according to the standards established for welded joints of category III.

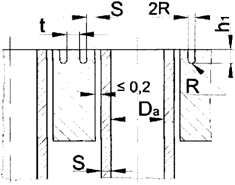

38. In case of unsatisfactory results of non-destructive testing of reference weld seams and overlays, depending on the nature of the identified defects, a decision is made to re-apply reference weld seams or overlays after additional operations to improve the quality of welding consumables or the impossibility of using controlled welding consumables for welding (surfacing) equipment and pipelines.

39. In case of unsatisfactory results of destructive testing tests should be repeated by a specific method of destructive testing on a doubled number of samples. The results of repeated tests shall be definitive.

40. Reference weld seams must be performed:

a) in the control of coated electrodes for manual arc welding - with electrodes of each batch;

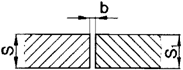

b) in the control of welding materials for automatic submerged arc welding and electroslag welding - with welding wire of each melting in combination with the flux of each batch;

c) in the control of welding materials for welding in a protective gas atmosphere (mixture of inert gases) - with welding wire for each melting combined with the protective gas of the same brand and same type (with a mixture of protective gases in the same proportions).

The reference weld seams should be made of welding materials used for industrial welding joints.

41. Reference overlays must be performed:

a) at control of the coated electrodes for manual arc surfacing - with electrodes of each batch;

b) in the control of welding materials for automatic submerged arc welding and electroslag welding - with welding wire or tape of each melting in combination with the flux of each batch;

c) in the control of welding materials for welding in a protective gas atmosphere (mixture of inert gases) - with welding wire for each melting or powder of each batch combined with the protective gas of the same brand and same type (with a mixture of protective gases in the same proportions).

Reference overlays should be made of materials used in the performance of industrial surfacing.

42. Instead of reference welding seams, reference surfacing is performed, provided that the batch (the set of batches of filler materials) of welding materials is to be used for welding parts:

a) of carbon or austenitic steels with a nominal thickness of up to 40.0 mm inclusive;

b) of silica-manganese steels with nominal thickness up to 30.0 mm inclusive;

c) of alloy steels or high-chromium steels with a nominal thickness of up to 20.0 mm inclusive.

43. If a batch (a set of batches) of welding materials is to be used both for welding, and for surfacing, only a reference welding seam is made, and in cases stipulated by paragraph 42 of these Rules, only a reference overlay.

44. To perform welding of parts with nominal thickness up to 20.0 mm, welding materials are used for welding of the root layers of the seam.

45. It is allowed not to perform reference welding seams if the design documentation provides for the performance of destructive testing of industrial welding joints.

46. When performing reference welding seams, the combination of grades of the base metal of the welded plates (parts) and the controlled welding materials must comply with the requirements of these Rules.

Plates made of steel of other grades of the same structural class are used on condition of preliminary surfacing of the edges subject to welding with welding materials of the controlled grade (combination of grades) not less than in three layers. For the specified surfacing of edges welding materials of other batches of welding materials of the same grade, including welding materials of other size, can be used.

Plates made of steel of other structural classes are used under the condition of preliminary surfacing on the edges of with at least five layers.

In the control of welding materials intended for welding of parts of steels of different structural classes, plates made of a material, on which no pre-surfacing of edges is required, are used.

47. When performing reference welding seams by automatic submerged arc welding or argon arc welding, three-layer edge welding shall be carried out by manual arc welding with coated electrodes approved for welding the same steels as the controlled welding materials.

48. The thickness of welded plates (parts) at performance of reference welding seams shall be established in process documentation with observance of the following conditions:

a) at use of a controlled batch (combination of batches) of welding materials for the production of welded joints with preliminary and accompanying heating, the thickness of the plates (parts) shall not be less than the thickness, beginning from which, according to these Rules, heating is required;

b) at use of a controlled batch (a combination of batches) of welding materials for the production of industrial butt-welded joints subject to thermal treatment, the thickness of plates (parts) should be not less than the thickness, starting from which, according to these Rules, heat treatment is required;

c) the thickness of the welded plates (details) shall be not less than 14.0 mm at arc welding and 30.0 mm - at electroslag welding.

49. The length of the welded plates (total length at welding of several pairs of plates), along the extent of a welded seam, shall provide selection of the necessary quantity of samples for carrying out all tests of metal of the seam provided by these Rules.

50. The width of each of the welded plates (parts) shall make not less than 300.0 mm at electroslag welding, not less than 150.0 mm at automatic submerged arc welding and not less than 80.0 mm at other methods of welding.

51. Dressing the edges of plates (parts) shall be allowed to carry out with any type of butt-welded joint used in welding the parts of appropriate thickness, or with a type of welded joints provided by documents on standardization for welding consumables included in the Consolidated List.

52. For performance of reference welding seams and overlays, welding equipment must be used ensuring the compliance of all the parameters of the welding conditions established by process documentation for the production of welded joints and surfacing.

Welding conditions must correspond to the modes used in the performance of one of the production welds with controlled welding materials.

Reference welding seams are performed in the lower position, unless other requirements are specified in the engineering documentation.

53. The necessity and temperature conditions of prior and accompanying heating at performance of reference welding seams shall conform to the requirements of these Rules established for production welded joints.

If a controlled batch (combination of batches) of welding materials is to be used for various production welds, for which the minimum prior heating and accompanying heating temperature specified in the process documentation differ by more than 50 °C (including the case where no heating is required), two reference seams shall be welded.

54. At welding of the first reference welding seam, the minimum heating temperature must correspond to the lowest temperature (including without heating), and at welding of the second one - to the highest of the minimum temperatures set for heating for welding of steel parts of the corresponding grades and thicknesses. If individual production parts are to be welded without heating, welding of the first reference seam shall also be carried out without heating.

55. The need, type and modes of heat treatment of reference welding seams must meet the requirements for the performance of production welded joints.

56. In case of repeated heat treatment of industrial welded joints, the same heat treatment should be applied to reference welding seams, as well.

In case of multiple tempering operations, the reference welding seam may be subjected to a single tempering operation with a duration of exposure at each temperature not less than 80% and not more than 100% of the total duration of the corresponding exposures at the heat treatment of industrial welded joints. First, exposure must be carried out at a lower temperature, then - at a higher temperature. The time of transition from one temperature to another is not counted in the duration of exposure.

The total exposure duration is defined as the sum of the nominal exposure durations (with tolerances not taken into account).

57. At different temperatures and (or) duration of exposure of tempering operations for industrial welded joints, for which the controlled batch (combination of batches) of welding materials is intended, it is allowed to produce two reference welding seams under the following conditions:

a) the first reference welding seam shall be subjected to the same tempering as the production welded joint, for which the lowest final tempering temperature with the shortest exposure time (in the case of a single production tempering) or the lowest final tempering temperatures with the shortest exposure time (in the case of multiple production tempering); in the cases, where the controlled welding materials will be used for the production of welded joints (both subject and not subject to tempering), the first reference welding seam shall not be subject to tempering;

b) the second reference welding seam shall be subjected to the same tempering as the production weld, for which the highest temperature of the final tempering is provided at the longest exposure time (in the case of a single production tempering) or the highest temperatures of the final tempering with the longest total exposure time (in the case of multiple production tempering operations); when determining the maximum total duration of exposure, one should take into account possible tempering after elimination of defects in industrial welded joints.

In the manufacture of the above reference welding seams, the results of weld inspection shall apply to all intermediate variants of multiple tempering operations of production welded joints.

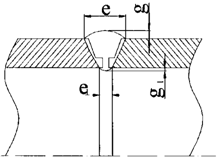

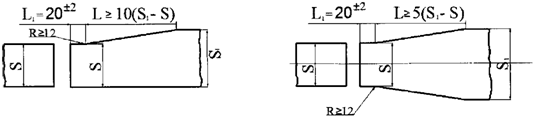

58. For implementation of reference overlays, plates of steel of pearlitic class are used, unless specific requirements are stipulated in the process documents.

The thickness of plates for performance of reference overlays shall make not less than 40.0 mm for corrosion-resistant surfacing and not less than 20.0 mm for other types of surfacing.

59. The modes of performance of reference surfacing should correspond to the modes used at performance of one of the production overlays with controlled welding materials.

Reference welding seams are performed in the lower position, unless other requirements are specified in the engineering documentation.

The necessity and modes of prior and accompanying heating of surfacing shall be determined by the process documentation.

60. In advance, surfacing of two layers shall be done on a plate (if the plate is made of steel of the same structural class, as the overlaid metal) or four layers (if the structural classes of steel of the plate and the overlaid metal are different) with welding materials of the controlled grade (combination of grades) of any batch (any combination of batches). Surfacing of all subsequent (reference) layers is carried out with welding materials of the controlled batch (controlled combination of batches).

61. The area, as well as the quantity and total height of layers of each reference overlay must ensure the selection of the necessary number of samples for performance of tests provided by federal rules and regulations in the field of atomic energy use regulating performance of control of metal of the equipment and pipelines of nuclear power installations at manufacture and installation.

62. The need, type and modes of heat treatment of reference overlays must meet the requirements for the performance of production overlays.

The performance of tempering of reference overlays (except for corrosion-resistant ones) shall be subject to the requirements for tempering of reference seams.

It is not allowed to perform heat treatment for reference overlays designed to determine the content of the ferrite phase in the overlaid metal. Samples for determination of the ferritic phase should be cut out before the heat treatment of the reference overlay, if the latter is intended for other types of tests.

63. Destructive testing at examination of the quality of welding (surfacing) materials before their use shall be carried out by testing samples cut from the control welding seams and overlays.

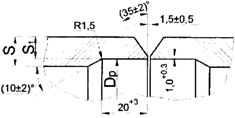

64. At destructive testing of welding (surfacing) materials intended for welding (surfacing) of parts made of steel, iron-nickel or aluminum alloys, the following characteristics of the weld metal or overlaid metal should be determined:

a) chemical composition;

b) mechanical properties (tensile strength, yield strength, elongation, relative contraction) at normal temperature;

c) mechanical properties at elevated temperature in the cases provided for in the engineering documentation;

d) critical brittleness temperature (or impact strength) in the cases provided for in the engineering documentation;

e) the content of the ferritic phase in the austenitic deposited metal in the cases provided by the documents on standardization of the material included in the Consolidated List;

f) resistance to intergranular corrosion of austenitic metal in the cases provided for in the engineering documentation.

The critical temperature of brittleness shall be confirmed in the cases provided for in the engineering documentation.

It is allowed not to carry out control of metal of the seam and the metal of overlay if the certificate on the material contains the results of tests conforming to requirements of federal rules and regulations in the field of atomic energy use regulating the performance of control of metal of the equipment and pipelines of nuclear power installations at manufacture and installation.

65. The results of non-destructive and destructive testing of the metal of overlay and the metal of the seam must meet the requirements of federal rules and regulations in the field of atomic energy use regulating the control of metal equipment and pipelines of nuclear power installations in the manufacture and installation.

66. Destructive testing at control of the quality of materials used for welding of parts made of titanium alloys shall only be carried out if there are requirements in the engineering documentation.

67. In case of unsatisfactory results of testing to determine the content of the ferritic phase there should be implemented a new reference seam (overlay) and testing shall be repeated to the same extent.

If unsatisfactory results are obtained for any other type of destructive testing, a double number of samples should be retested. The results of repeated tests shall be definitive.

68. At control of coated electrodes, or a wire containing no titan or niobium and intended for argon arc welding in the environment of argon and in mixtures of argon with helium, carbon dioxide and oxygen, data from certificates on chemical composition shall be accepted as results of control.

69. At control of coated electrodes, mechanical properties of the seam or overlay metal at normal and (or) increased temperatures shall not be determined:

a) if the electrodes are intended for non-heat-treated welded joints (surfacing), and the certificate shows the relevant characteristics of the weld metal (surfacing metal);

b) if the certificate for the batch of electrodes provides the corresponding characteristics of the weld seam metal or overlay metal after a heat treatment, the modes of which correspond to modes of heat treatment of production welded connections (surfacing) are given.

70. The critical temperature of brittleness of the weld seam metal or overlay metal is not determined in the following cases:

a) if the certificate for the batch of electrodes contains results of determination (or confirmation) of the critical temperature of brittleness with a heat treatment, the modes of which correspond to modes of heat treatment of production welded joints (surfacing);

b) if the welding materials are intended for welding (surfacing) of parts and assembly units that are not subject to the calculation of brittle fracture resistance in accordance with the engineering documentation;

c) for austenitic welding materials and iron-nickel, titanium and aluminum alloys;

d) in the control of filler materials for argon arc welding designed for welding of the root portion of the weld (with the exception of the butt welds of categories I and In) and welding of parts with the rated thickness up to 16.0 mm inclusive (for smaller thickness);

e) at control of the welding (surfacing) materials intended only for performance of the first layer of surfacing adjoining to the base metal of any kind.

71. The content of the ferritic phase in the overlaid metal must meet the requirements of federal rules and regulations in the field of atomic energy use regulating the control of metal equipment and pipelines of nuclear power installations in the manufacture and installation.

72. Resistance to intergranular corrosion shall be checked at control of the welding materials which are subject to use for welding (surfacing) of parts and assembly units from austenitic steels operating in water, steam-water and steam environments, or for surfacing of the top layer of corrosion-resistant surfacing.

73. Reference seams (overlays), from which samples are cut for testing the resistance to intergranular corrosion, shall be subjected to heat treatment, if it is provided for industrial welded joints (surfacing). In the presence of several modes of heat treatment of industrial welded joints (surfacing), heat treatment should be carried out according to one of these modes, the most unfavorable in terms of resistance of the weld seam (overlaid) metal intergranular corrosion. The mode of heat treatment is established by process documentation.

V. Preparation and assembly of parts for welding (surfacing)

74. Preparation and assembly of parts (assembly units) for welding (surfacing) should be carried out according to the process documentation, which, at least, should specify:

a) accessories and equipment used in the assembly;

b) the order and sequence of assembly;

c) ways of fastening of parts;

d) methods of welding, welding materials and welding modes in the performance of tacks and welding of temporary service fasteners;

e) size, quantity and location of tacks;

f) the number of temporary service fastenings, their arrangement and the sizes of seams welding the same to parts;

g) methods of assembly quality control.

75. Process documentation for assembly is allowed to be combined with the process documentation on welding (surfacing).

76. Preparation of edges and surfaces of parts for welding and surfacing should be performed by machining.

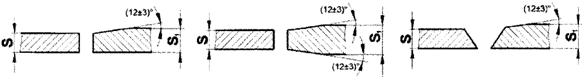

77. Preparation of edges of carbon and silicon-manganese steel parts shall be performed by oxygen, air-arc, plasma-arc or laser cutting, followed by machining to remove cutting marks.

78. Preparation of edges of parts of alloyed steels shall be carried out by oxygen, air-arc, laser and plasma-arc cutting on condition of the subsequent removal by machining of a layer of metal of the following thickness:

a) not less than 1.0 mm, for metal with a guaranteed yield strength of 315 MPa inclusive at a temperature of 20 °C;

b) not less than 2.0 mm for metal with a guaranteed yield strength of more than 315 MPa at a temperature of 20 °C.

For steels containing niobium, cutting should be carried out with preheating of the metal.

79. Preparation of edges of parts of austenitic steels shall be carried out by plasma-arc or oxygen-flux cutting, followed by removal of the metal layer with a minimum thickness of 1.0 mm by machining.

80. Preparation of edges of parts made of pearlite and austenitic steels shall also be performed by waterjet cutting.

No machining is required after waterjet cutting.

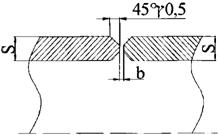

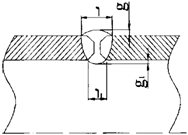

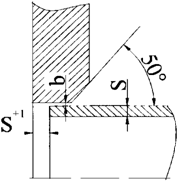

81. At design preference shall be given to the types of welded connections given in the Appendix N 5 to these Rules.

Categories of welded joints not stipulated herein may be used subject to assurance of strength and compliance with requirements of federal rules and regulations in the field of atomic energy use regulating control of metal of the equipment and pipelines of nuclear power installations at production and installation.

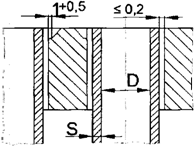

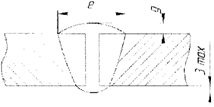

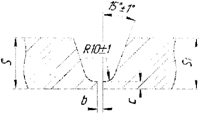

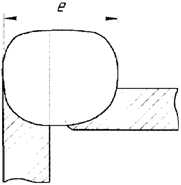

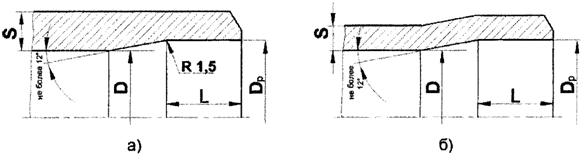

82. Smooth transition <1> from one component to another shall be ensured in butt weld joints of components with different nominal wall thickness. Specific forms of the above transition shall be established in engineering (design) documentation, proceeding from requirements of strength calculation and performance of control by the methods provided by federal rules and regulations in the field of atomic energy use regulating control of metal of the equipment and pipelines of nuclear power installations at production and installation.

--------------------------------

<1> Geometric dimensions of the smooth transition shall be assigned in each case in accordance with the requirements of the engineering documentation.

83. When preparing pipes of one nominal diameter with the same nominal wall thickness for butt-welded joints with one-sided cutting of edges, if required by the engineering documentation, calibration (boring or expansion) of the pipe ends to a given internal diameter should be performed.

84.Edges prepared for welding (surfaces for overlaying) and the adjacent surfaces of parts must be cleaned of surface contamination (in case of welding of titanium alloys - cleaned of tarnishing traces, as well). The width of the specified areas shall be not less than 20.0 mm at preparation of parts for arc welding (surfacing) and not less than 50.0 mm - at preparation for electroslag welding.

85. The edges of aluminum alloy parts to be welded must be cleaned mechanically or chemically prior to assembly.

General assembly requirements

86. All parts and assembly units received for assembly must have marking and (or) accompanying documentation confirming the fulfillment of previous operations. The method of marking shall be determined by the manufacturer (installation or repair organization).

87. Assembly of parts (assembly units) for performance of butt welds with annular seams should be carried out on the assembly and welding equipment or devices that ensure the alignment of the parts (assembly units) to be joined.

88. No tacks shall be allowed at the intersection or interface of two or more joints to be welded.

89. Defective tacks must be removed by machining.

Defective tacks shall be removed by air-arc gouging, subject to subsequent mechanical dressing with the removal of gouging marks and a layer of metal to the following thickness:

a) not less than 1.0 mm - for parts made of austenitic steel or alloy steel with a guaranteed yield strength up to 315 MPa inclusive at a temperature of 20 °C;

b) not less than 2.0 mm - for parts of high-chromium steels or alloy steels with a guaranteed yield strength of more than 315 MPa at a temperature of 20 °C.

90. The surface of the parts in the places of welding of temporary service fasteners should be first cleaned of contamination.

91. Seams of welding of temporary service fasteners shall be located at a distance not less than 60.0 mm from the edges which are subject to welding, at assembly for welding of parts made of carbon and silica-manganese steels - not less than 30.0 mm.

92. It shall not be allowed to increase the dimensions of the metal surfacing parts unless stipulated by repair documentation.

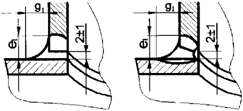

93. In accordance with the requirements of the engineering documentation, assembly for connections of cylindrical parts of equipment and pipelines of groups B and C should be carried out on welded backing elements (rings, ridges).

94. In the joints of parts assembled for arc welding with double-sided cutting edges, the displacement of root faces should not exceed 0.5 mm at a nominal root face height of up to 1.0 mm inclusive, half of the nominal root face height at its value of more than 1.0 to 4.0 mm inclusive, and 2.0 mm at a nominal root face height of more than 4.0 mm.

95. Offset (misalignment) of the inner edges in the butt welds with one-sided cutting should not exceed 12% of the nominal thickness of the joined edges, but anyway not more than 0.5 mm.

96. In the butt-welded joints assembled for electroslag welding, the displacement of the edges of parts to be welded must not exceed 2.0 mm.

97. In butt-welded joints of parts assembled for arc welding, of the same nominal thickness S, not to be machined after welding in the zone of welds, the permissible displacement of edges (the discrepancy between the surfaces of the parts to be joined) from the side (sides) of welding shall not exceed the standards listed in table No. 1 of these Rules.

Table No. 1

Nominal thickness of the welded components S, mm | Maximum permissible displacement (misalignment) of edges in butt joints, mm | ||

with longitudinal, meridional, chordal and circular seams, as well as with ring seams for welding of bottom plates | with ring seams | ||

at welding of pipes and conical parts | at welding of cylinder-shaped housing parts of sheets or forged pieces | ||

Up to 5.0, inclusive | 0.20S | 0.20S | 0.20S |

Over 5.0 and up to 10.0, inclusive | 0.10S+0.5 | 0.10S+0.5 | 0.25S |

Over 10.0 and up to 25.0, inclusive | 0.10S+0.5 | 0.10S+0.5 | 0.10S+1.5 |

Over 25.0 and up to 50.0, inclusive | 0.04S+2.0 | 0.06S+1.5 | 0.06S+2.5 |

Over 50.0 and up to 100.0, inclusive | 0.02S+3.0 | 0.03S+3.0 | 0.04S+3.5 |

Over 100.0 | 0.01S+4.0, but not exceeding 6.0 | 0.015S + 4.5, but not exceeding 7.5 | 0.025S+5.0, but not exceeding 10.0 |

98. In the joints assembled for welding, the geometric position of the axes of parts must meet the requirements of the engineering documentation.

99. When transporting the assembled parts (assembly units) to the welding site, conditions must be provided to prevent the destruction of the tacks or seams of the welding of temporary service fasteners, as well as damage and (or) contamination of the parts assembled for welding.

Assembly of parts of steels and iron-nickel alloys

100. To perform tacks and welding of temporary service, it is allowed to use arc welding with coated electrodes or argon arc welding.

At assembly of parts for argon-arc or electron-beam welding (including at argon-arc welding of the root part of a seam) tacks should be made by argon-arc welding.

101. Welding of temporary process fasteners should be carried out according to the process documentation containing information on steel grade, shape, size, number and location of these fasteners, qualifications of welders engaged in welding of fasteners, welding materials, methods and modes of welding and heating.

Temporary process fasteners at assembly of parts made of austenitic steels and iron-nickel alloys should be used when the nominal thickness of the parts is not less than 6.0 mm.

102. Tacking and welding of temporary process fasteners at assembling parts made of alloyed and high-chromium steels should be performed with a heated metal in the weld zone according to the mode set for the weld in question, except for welding of tacks of fasteners with austenitic welding materials.

103. Heating at tacking is not mandatory for welded joints, where the root of the seam is made by argon arc welding without heating.

104. At making tacks for assembly of parts (assembly units) welding materials should be applied intended for implementation of welded joints of parts made of steel (alloys) of the relevant grades.

At the assembly of parts made of steels of pearlitic class (except for parts of steel grades 15Kh2MFA-A, 15Kh2NMFA class 1, 15Kh2MFA-A mod. A, 15Kh2MFA-A mod. B, 15Kh2NMFA and 15Kh2NMFA-A, to be joined to each other), the following must be used for tacking:

a) the electrodes of the grades UONII-13/45, UONII-13/45A, UONII-13/45АА and UONII-13/55, TsU-7, TsU-7A and TMU-21U - for manual arc welding with coated electrodes (with the assembly of parts in contact with liquid metal coolant, the electrodes of the first three grades shall only be applied);

b) welding wire of grades Sv-08GS and Sv-08G2S - for argon arc welding.

To perform tack welding at the assembly of parts made of steel of grades 15Kh2MFA-AD, 15Kh2MFA-A mod. A, 15Kh2MFA-A mod. B or 15Kh2NMFA-A to be joined to each other, there should be applied the welding materials given in table No. 2.1 of Appendix No.2 to these Rules.

105. When assembling parts made of pearlitic steels and (or) of high-chromium steels, temporary process fasteners of steel of the same grade as the assembled parts or of carbon steels should be used, and when assembling parts made of austenitic steels, iron-nickel alloys and (or) of two-layer steels (with welding of fasteners to the cladding layer) - of steel of grade 08Kh18N10T.

106. For welding of temporary process fasteners to parts (assembly units) made of steels of pearlitic class without corrosion-resistant surfacing, the same welding materials shall be used as those applied for implementation of tacks in compliance with requirements for heating of base metal. Coated electrodes of grades ZIO-8, TsL-25/1, EA-395/9, TsT-10 and welding wire of grades Sv-10Kh16N25АМ6, Sv-07Kh25N13 shall be applied without heating of the base metal.

107. For welding of temporary process fasteners to parts (assembly units) of high-chromium steels, there should be used:

a) coated electrodes of grades EA-395/9, TsT-10, TsL-25/1, TsL-25/2, ZIO-8 or welding wire of grades Sv-10N16N25AM6 or Sv-07Kh25N13 - for welding of fasteners made of carbon and high-chromium steels to steel parts that do not contain niobium, without heating the base metal;

b) coated electrodes of grades TsL-25/1, TsL-25/2, ZIO-8 or the welding wire of grade Sv-07Kh25N13 for welding of fasteners of high-chromium steel to parts of steel containing niobium, without heating.

108. For welding of temporary process fasteners to parts (assembly units) of austenitic class steels, there should be used:

a) coated electrodes and welding wire approved for welded joints - for welding of austenitic steel fasteners;

b) coated electrodes of grades EA-395/9 and TsT-10 or the welding wire grade Sv-10Kh16N25АМ6 - for welding of fasteners made of carbon steel.

109. For welding of temporary process fasteners to parts of iron-nickel alloys, coated electrodes must be used, or the welding wire allowed for performance of welded joints of parts made of an alloy of the relevant grade.

110. For welding of temporary process fasteners to the cladding layer (corrosion-resistant surfacing) of parts made of two-layer steels, coated electrodes or the welding wire allowed for performance of the top layer of corrosion-resistant surfacing shall be applied.

In the case of the use of carbon steel fasteners on the ends to be welded, a preliminary two-layer surfacing must be performed in compliance with the following requirements:

a) in case of the presence of niobium or titanium in the metal of anti-corrosion overlay, the first surfacing layer shall be made with coated electrodes of grades TsL-25/1 or ZIO-8, or the welding wire of grade Sv-07Kh25N13 and the second layer, with electrodes of grades TsT-15K or EA-898/21B, or welding wire of grades Sv-04Kh20N10G2B or Sv-08Kh19N10G2B;

b) in the absence of niobium or titanium in the metal of corrosion-resistant overlay, the both layers shall be made with coated electrodes of grades TsL-25/1 or ZIO-8, or the welding wire of grade Sv-07Kh25N13.

111. Temporary process fasteners shall be removed by mechanical means. Complete removal of temporary process fasteners with oxygen or air-arc cutting without embedding into the base metal, followed by grinding the surfaces of parts to remove traces of cutting should be performed on parts of carbon and silicon-manganese steels.

On parts of alloyed and high-chromium steels, as well as of austenitic steels, incomplete removal of temporary process fasteners with oxygen (oxygen-flux), plasma-arc or air-arc cutting is allowed. The remaining part of the fastening must be at least 4.0 mm high and shall be mechanically removed.

At removal of temporary process fasteners, incomplete removal of metal of their welding seams is allowed. In the case of welding of temporary process fasteners with austenitic welding materials to parts made of steel of pearlitic class, and of high-chromium steels, and in case of welding fasteners made of carbon steel with these materials to parts made of austenitic steels, incomplete removal of austenitic weld metal should be done from the side not in contact with the working media, and for corrosion-resistant surfacing - from either side.

112. If the clearance exceeds the norms established in Appendix No. 5 to these Rules by not more than half the nominal thickness of the parent metal in the zone subjected to welding of edges, but not more than 10.0 mm, surfacing must be done for the edges (one or two) with coated covered electrodes or welding wire (in case of argon arc welding) of the grades stipulated for the welded joint in question. When surfacing only the root part of the edges of the parts to be joined made of pearlite steel, welding materials used for welding the root part of the seam of this joint should be used. Surfacing should be carried out with heating, if this is provided for the welded joint to be made. After surfacing, the edges are machined to the specified geometric shape. Parts of alloyed and high-chromium steels must be subjected to heat treatment in the intermediate tempering mode (if stipulated) prior to machining of the edges.

Heating during surfacing and heat treatment of the overlaid edges shall not be carried out if the volume of metal deposited on the edges of carbon and silicon-manganese steel parts does not exceed 20 cm3.

113. The remaining backing rings shall be made of the following materials:

a) for welding of parts of materials of the same grade - of the material of the same grade as the welded parts;

b) for welding of parts of steel grades of pearlitic class, as well as for welding of parts made of high-chromium steel of different grades - of the least alloyed steel of compatible grades;

c) for welding of parts of austenitic steels of different grades, as well as for welding of parts of austenitic steels with parts of pearlitic steels or of high-chromium steels with pre-surfacing of edges with austenitic welding materials - of steel of grade 08Kh18N10T, or of austenitic steel of the same grade as one of the welded parts;

d) for welding of parts of steels of pearlitic class with parts of high-chromium steels - of high-chromium steel of the same grade as one of welded details at performance of welded joint with high-chromium welding materials, or of austenitic steels at performance of welded joint with austenitic welding materials;

e) for welding of parts of iron-nickel alloys among themselves and with parts of steels of austenite class - of iron-nickel alloy;

f) for welding of pipes of titanium alloys - of forged or rolled rods of alloys of grades VT 1-00. VT 1-0, or of pipes of alloys of grades PT-1M and PT-7M, regardless of the grade of alloy of the connected pipes; application of forged or rolled rods of alloys of grades PT-3V and 3M is allowed;

g) for welding of parts of titanium alloys, made of sheet metal, bent sheet metal or forged blanks and forgings - of the same types of semi-finished products, for connections of cast and welded structures - of sheet metal or forgings; here, there must be used semi-finished products of alloys of grades VT1-00, VT1-0 and PT-3V, regardless of the grade of the base metal alloy, or combination of alloys.

At the operating temperature up to 450 °C, the remaining backing rings of carbon steel should be used for implementation of welded joints of parts made of steels of pearlitic class, regardless of their grade.

114. After the completion of the assembly for manual arc welding with coated electrodes, parts of austenitic steel and iron-nickel alloys adjacent to the edges of the surfaces should be protected from splashes of molten metal. The width of the protected area shall be not less than 100.0 mm in each side from the edges prepared for welding. At welding of temporary process fasteners to the surfaces of parts made of steels of austenitic class should be used for similar protection. Methods of protection shall be established in the process documentation.

The requirement of the first paragraph of this item is not obligatory if the performed welded joints are subject to subsequent machining with removal in the specified zone of a layer of metal not less than 0.5 mm thick.

Assembly of aluminum alloy parts

115. Welded edges, and adjacent surfaces must be cleaned mechanically or chemically.

116. Tacking must be done by manual or semi-automatic argon arc welding with the same welding materials and in the same modes as welding. Tacks having a silver color and having no pores or cracks are considered to be of proper quality. Defective tacks must be removed by machining.

The length of the tacks and the distance between them should be selected depending on the thickness of the welded parts in accordance with table No. 2 of these Rules.

Table No. 2

Thickness of welded metal, mm | Tack length, mm | Distance between tacks, mm |

from 2.0 to 4.5 | from 20.0 to 25.0 | from 100.0 to 150 |

from 5.0 to 8.0 | from 30.0 to 35.0 | from 150.0 to 200.0 |

from 8.0 to 30.0 | from 40.0 to 50.0 | from 200.0 to 250.0 |

Extreme tacks must be located at a distance of 10.0 - 20.0 mm from the edge of the joint.

117. With the nominal thickness of parts not less than 6.0 mm, welding of temporary process fasteners shall be applied in the cases provided by process documentation. The process documentation should contain information about the grade of aluminum alloy, the dimensions, number and location of fasteners, on welding materials, methods and modes of welding.

Temporary process fasteners shall be removed mechanically with obligatory dressing of locations of their welding. Application of abrasive tools at dressing is not allowed. Damage to the surface bringing the thickness beyond the minus tolerance of metal shall not be permitted.

Capillary inspection (or visual inspection using a magnifying glass with 4-7 magnification factor) shall be carried out in the zones of welding of fasteners made of alloys of grades AB and SAV1after prior dressing of the surface to a roughness of not more than Ra 5 microns (Rz 20 microns) .

118. In the butt joints assembled for welding, the offset of inner edges must not exceed 10% of the thickness of the material along the entire length of the joint (but not more than 0.6 mm) or up to 15% of the thickness of the material (but not more than 1.2 mm) in areas with a length of up to 20% of the length of the seam.

119. Parts intended for the manufacture of pipelines should be stored in a package after cleaning and assembly operations. The shelf life prior to welding shall not exceed 3 days.

Assembly of titanium alloy parts

120. The edges and adjacent surfaces must be degreased after dressing. Welding of temporary process fasteners and lead-out strips and tacks must be implemented with the same welding materials as the main seam with the obligatory protection of the reverse side by blowing with a protective gas. Tacks must be of silver color.

Temporary process fasteners welded to sheet structures must be removed by gas cutting. The cutting line must be at least 10.0 mm away from the surface of the structure.

Edges of pipes and parts intended for the manufacture of pipelines should be stored in a package after dressing and assembly operations. The shelf life of assembled pipe joints shall not be more than 5 days (no more than 36 hours, if the parts were etched).

VI. Welding

General requirements

121. Welding of parts (assembly units) should be carried out according to the process documentation. Welding modes for welded joints are given in Appendix No. 6 to these Rules. The process documentation for welding must establish:

a) welding (surfacing) methods;

b) welding conditions as applied to the implementation of specific welded joints;

c) requirements to welders' qualifications;

d) types of welded joints performed;

e) type and polarity of welding current;

f) welding equipment in use;

g) combinations of grades of base and welding (surfacing) materials;

h) the necessity, techniques and modes of prior and accompanying heating at welding (surfacing);

i) spatial positions of welding (surfacing);

k) the grade and diameter of the electrode and (or) wire, the width, thickness and grade of the tape;

l) requirements for the preparation and baking of welding materials;

m) materials, methods and modes of performance of tacks or instructions on welding of temporary process fasteners;

n) the procedure for laying beads and layers of the seam and overlays;

o) types of heat treatment of welded joints and overlaid parts (if any));

p) gas protection requirements (for argon arc welding);

q) conditions of exposure of welded joints (overlaid parts) from the end of welding (surfacing) to the beginning of heat treatment;

r) methods and scope of operational control of welding (surfacing).

122. For the implementation of welded joints of parts made of steel and iron-nickel alloys, the following welding methods must be applied:

a) automatic submerged arc welding;

b) manual arc welding with coated electrodes;

c) automatic, semi-automatic and manual argon arc welding with consumable and non-consumable electrode;

d) electroslag welding;

e) electron beam welding in vacuum;

f) diffusion welding for steel and zirconium pipe joints.

Argon arc welding shall be carried out in the environment of the protective gases specified in Appendix No. 2 to these Rules.

Semi-automatic welding in gaseous carbon dioxide with welding wire of grade Sv-08G2S should be used to perform welded joints of category III in parts of carbon and silicon-manganese steel.

123. It is allowed to use two or more welding methods from among the aforesaid to perform a single welded joint (combined welding).

124. Welding (surfacing) must be carried out in conditions that protect the welding site from precipitation, moisture, drafts and other impacts that affect the quality of welding.

Welding (surfacing) in the manufacture of equipment and assembly units of pipelines, as well as the implementation of welded joints of categories I, In, II, IIn during installation is not allowed at ambient temperatures below 5 °C.

Welded joints of category III on equipment and pipelines during installation must be carried out at an ambient temperature not lower than minus 15 °C.

The ambient air temperature, at which welding (surfacing) shall be performed during the repair of equipment and pipelines is set in the process regulations by the operating organization.

125. At ambient temperatures below 5 °C, welding (surfacing) of parts made of pearlite and high-chromium steels must be carried out with additional or enhanced heating. For non-heated welds, the minimum prior and accompanying heating temperature must be at least 50 °C (additional heating). For welded joints with mandatory heating, the minimum heating temperature must be increased by 50 °C (enhanced heating).

126. Requirements to heating at welding (surfacing) are given in Appendix No. 7 to these Rules.

127. Before being subjected to welding (surfacing), the parts of austenitic class assembled for welding must be degreased.

128. The root part of the seam should make no more than 30% of the nominal thickness of the welded parts (the design height of the fillet weld), but not more than 20.0 mm.

129. At the performance of multiple-pass weld seams and overlays after the application of each bead, the seam surfaces and the dressing edges should be cleaned of slag, splashes of metal and visually examined for cracks, unacceptable slag or tungsten inclusions, pores, irregularities and other defects. The results of the control must comply with the requirements of federal rules and regulations in the field of atomic energy use regulating the control of metal of equipment and pipelines of nuclear power installations at the manufacture and installation. The defects must be removed mechanically before welding can be resumed.

130. All of the shrinkage holes (craters) must be brought to removable allowances of parts (or to mounting straps), or filled.

131. Welding of fillet seams, which, according to engineering documentation, are subject to tightness requirements, shall be carried out in at least two layers.

132. Partial or complete removal of the root part of the weld before welding on the second side should be performed at two-sided welding (including the implementation of the back-up weld).

A double-sided welding joint (or a single-sided weld with the root pass) must be performed with alternate cutting the edges and welding on one side, followed by cutting and welding on the other side.

At two-way welding of parts made of austenitic steel and iron-nickel alloys, the beads facing the working media must be the last to be made.

133. Welding of multi-pass welds of austenitic steels and iron-nickel alloys must be stopped after each pass to cool the metal to a temperature not exceeding 100 °C.

For welding austenitic steels with a ferritic phase content of 4 - 8%, a periodic temperature increase up to 250 °C is allowed.

134. After welding, the weld surface and the surface of the adjacent area of the base metal must be cleaned of slag and metal splashes to the width required for subsequent inspection.

135. Manual arc welding (surfacing) with coated electrodes with rods of austenitic steel should be performed in narrow beads with a width of not more than three diameters of the electrodes used.

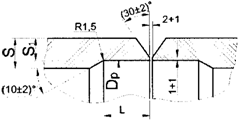

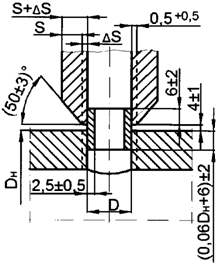

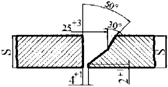

136. Welding of the root portion of the seam of welded joints of parts made of steel grade 08Kh18N12T and iron-nickel alloys as well as pipes made of carbon steel with a nominal wall thickness of 12.0 mm must be performed with application of filler wire.

Welding of parts made of steels of different structural classes

137. Welding materials for performance of welded joints of parts made of steels of different structural classes, including for preliminary surfacing of edges, shall be applied according to requirements of tables N 2.2, 2.4, 2.6 and 2.8 of Appendix No. 2 to these Rules.

138. At welding of parts made of austenitic steel with parts made of carbon and silicon-manganese steels with a nominal thickness of more than 10.0 mm, the edges of parts made of carbon and silicon-manganese steels should be subject to prior surfacing, the thickness of which after machining should be:

a) 6.0 +/- 2.0 mm - for manual arc welding with coated electrodes and argon arc welding;

b) 9.0 +/- 2.0 mm - for automatic submerged arc welding.

Manual arc welding with coated electrodes and argon arc welding on edges deposited for automatic submerged arc welding is allowed.

139. At welding of parts of austenitic steel with parts of alloyed and high-chromium steels with a nominal thickness of more than 6.0 mm, the edges of parts of alloyed and high-chromium steels should be subject to prior surfacing, the total thickness of which after machining should be 9.0 +/- 2.0 mm at the thickness of the first layer 3.0 +/- 1.0 mm.

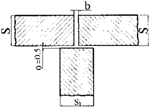

140. The need for prior surfacing of edges at performing fillet, T-shaped and lap welds of carbon and silicon-manganese steel with parts of austenitic steel shall be determined by the calculated height of the fillet seam (instead of the nominal thickness) in accordance with the requirements of paragraph 138 of these Rules.

141. At automatic submerged-arc welding of parts made of steels of pearlitic class with parts of high chromium steels, the edges of parts made of steels of pearlitic class must be subjected to prior surfacing with coated electrodes intended for welding of parts made of high-chromium steel. The above surfacing shall be carried out in at least three layers and have the overall thickness after machining not less than 7.0 mm.

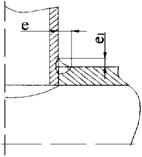

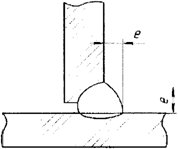

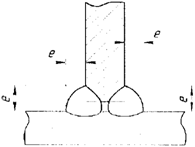

142. For welding at installation and repair of pipes of steels of different structural classes, in case of absence of prior surfacing on their edges made by the manufacturing organization, special factory-made adapters shall be applied.

An adapter is an assembly unit welded of two pipe segments, each of which must correspond to the steel grades of the pipes to be connected. Application of the above adapters shall be provided by engineering documentation.

143. At intersections of seams of austenitic and pearlite welding materials, the welding with pearlite materials must be the first to be carried out.

144. The width of the surface of the metal of the weld or overlay applied at prior surfacing made with electrodes of the grade EA-395/9, TsT-10 or welding wire of the grade Sv-10Kh16N25AM6, which faces the water, water-steam or steam medium of the coolant, shall not exceed 7.0 mm.

Welding of parts of two-layered steels

145. When preparing parts of two-layer steels for welding, the cladding layer in areas adjacent to the edges subject to welding (from the side of their opening), and the areas of application of fillet welds, must be removed, unless otherwise stipulated in this subsection.

The width of the zone of removal of the cladding layer shall be not less than 5.0 mm for manual arc welding with coated electrodes and argon arc welding and not less than 10.0 mm for automatic submerged arc welding. For fillet and t-shaped joints, the area of removal of the cladding layer needs to extend beyond the fillet weld for not less than the specified width values.

For welded joints, the basic layer of which made of pearlite steel is subjected to ultrasonic and (or) radiographic control prior to the application of the cladding layer, the width of the area of removal of the cladding layer must be such that the above control would be possible.

146. When performing welded joints with the removal of the cladding layer, the welding of the basic layer of pearlite steel shall be carried out first, and then welding (surfacing) of the cladding layer.

147. Welding of the basic layer should be carried out with welding materials designed for welding of parts without a cladding layer.

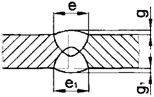

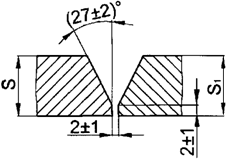

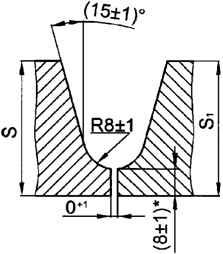

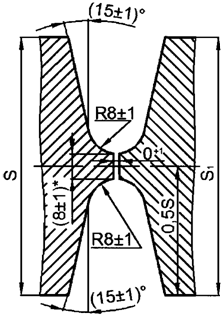

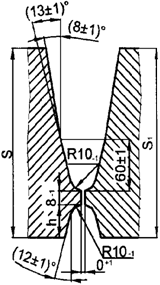

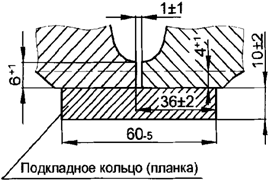

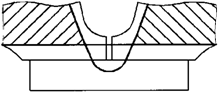

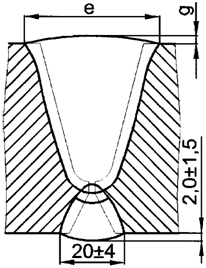

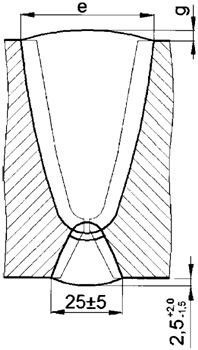

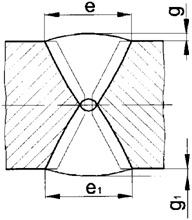

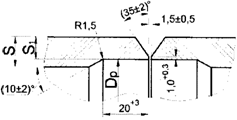

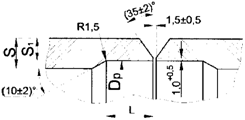

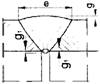

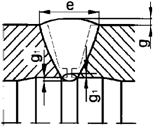

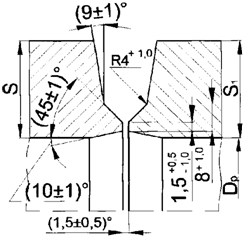

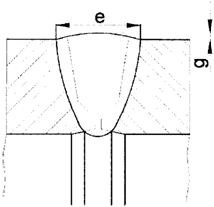

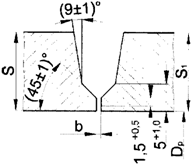

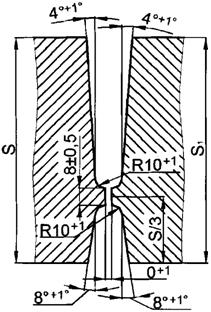

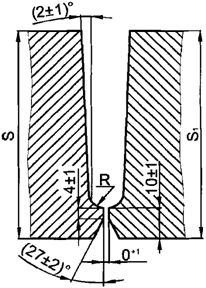

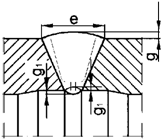

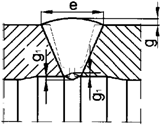

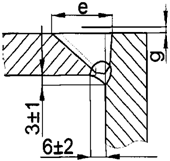

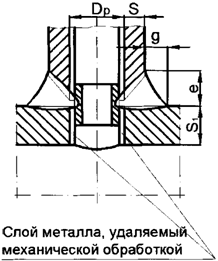

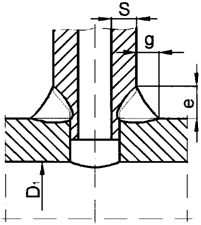

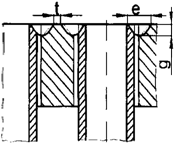

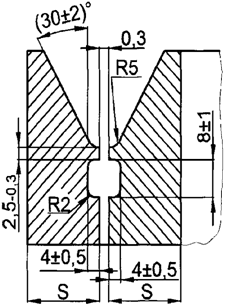

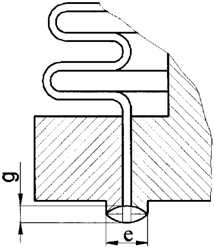

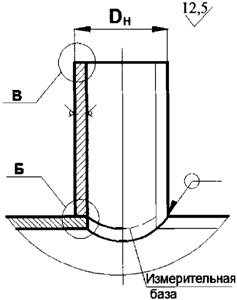

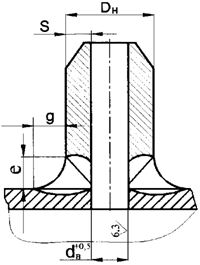

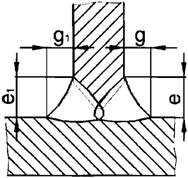

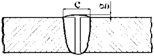

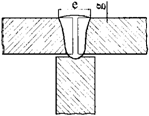

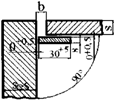

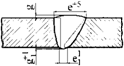

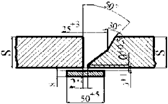

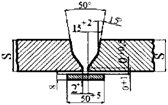

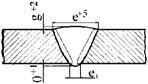

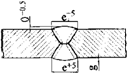

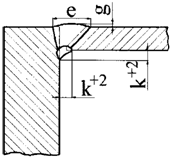

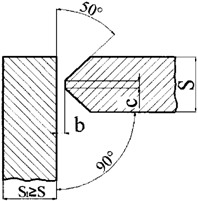

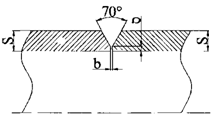

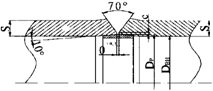

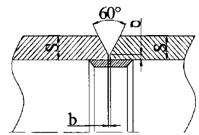

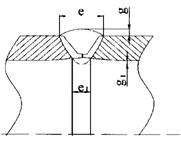

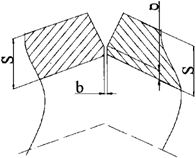

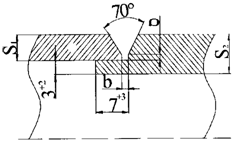

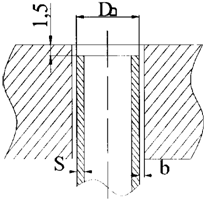

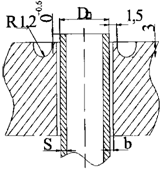

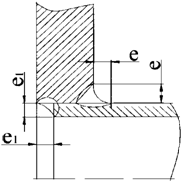

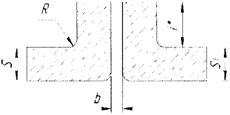

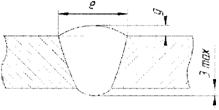

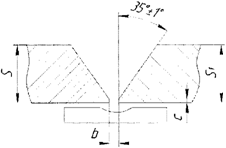

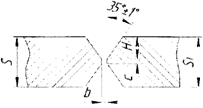

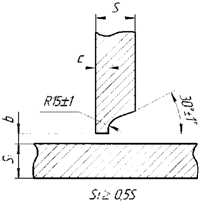

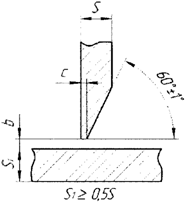

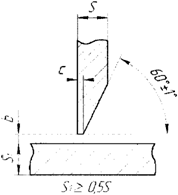

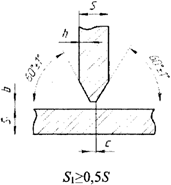

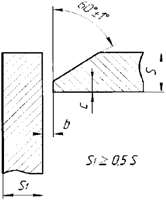

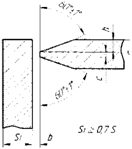

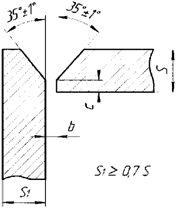

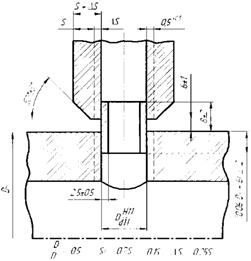

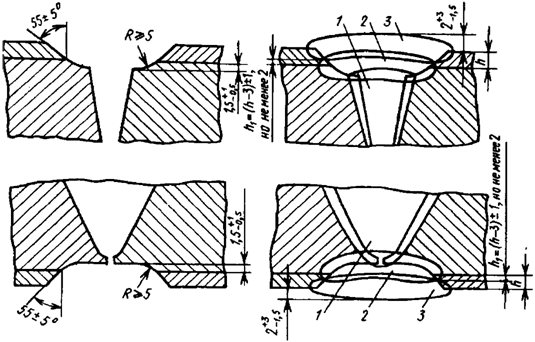

148. Welding (surfacing) of the cladding layer on the seam zone of welding of two-layer steels includes the surfacing of separating and protective surfacing (figure 1).

149. The separating surfacing must be performed with coated electrodes of grades EA-23/15, TsL-25/1 or ZIO-8, welding wire of grade Sv-07Kh25N13 (in case of argon arc welding), welding tape of grades Sv-07Kh25N13, Sv-07Kh25N13А Sv-02Kh23N15 in combination with fluxes of grades OF-10, OF-40, FTs-18 (for automatic submerged surfacing). The dimensions of the welded joint elements shall correspond to those shown in figure 1.

Removing the weld reinforcement should not lead to contact between the separating surfacing and the medium.

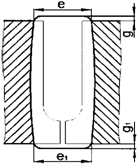

Figure 1. The arrangement of dressing and implementation of welded

joints of parts of two-layered steels:

1 - weld seam;

2 - separating surfacing;

3 - protective surfacing;

150. Protective surfacing must be carried out in at least two layers with the following welding (surfacing) materials:

a) if the welded joint is not subject to heat treatment - with welding materials specified in paragraph 149 of these Rules, or with coated electrodes of grades EA-400/10U, EA-400/10T, TsT-26, TsT-26M, EA-898/21B, TsT-15K, TsL-25/2, or welding wire of grades Sv-04Kh19N11М3, Sv-04Kh20N10G2B Sv-08Kh19N10G2B (in case of argon arc surfacing), or with welding tape of grades Sv-04Kh19N11М3, Sv-04Kh20N10G2B, Sv-08Kh19N10G2B in combination with the flux of grades OF-10, OF-40 or FTs-18 (for automatic submerged surfacing);

b) if the welded joint is subject to heat treatment - with coated electrodes of grades EA-898/21B or TsT-15K, or welding wire of grades Sv-04Kh20N10G2B, Sv-08Kh19N10G2B (in case of argon arc surfacing), or with welding of grades Sv-04Kh20N10G2B, Sv-04Kh20N10G2BA or Sv-08Kh19N10G2B, in combination with the flux of grades OF-10, OF-40 or FTs-18 (for automatic submerged surfacing).

151. Protective and separating surfacing by manual arc welding with coated electrodes should be carried out in separate longitudinal beads with a width of not more than three diameters of the rod of the electrode used.

152. Welding of parts with the rated thickness of the base layer (for fillet and t-welds with the design height of fillet weld) of carbon steel and silico-manganese steels to 36.0 mm inclusive, and of alloyed steel up to 6.0 mm inclusive, should be performed with coated electrodes of grades EA-855/51, EA-32/53 or welding wire of grades Sv-03Kh15N35G7М6B, Sv-03Kh20N65G5М4B3V (in case of argon arc welding) throughout the thickness from either side without removing the cladding layer.

If the metal of the cladding layer does not contain niobium and the welded joint is not subject to heat treatment, welding of the base layer with a thickness of not more than 10.0 mm should be performed with coated electrodes of grades EA-395/9 or TsT-10, or welding wire of grade Sv-10Kh16N25AM6 (with argon arc welding) to a level that overlaps the line of fusion with the cladding layer by not less than 1.0 mm, and the separation and protective surfacing - with coated electrodes of grades EA-400/10U, EA-400/10T, TsT-26, TsT-26M or welding wire of grade Sv-04Kh19N11M3 (at argon arc surfacing) in not less than two layers.

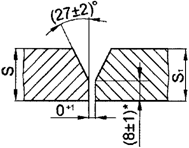

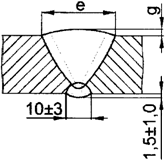

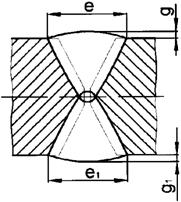

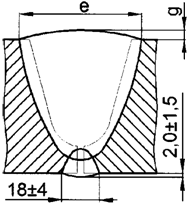

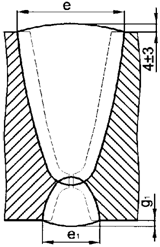

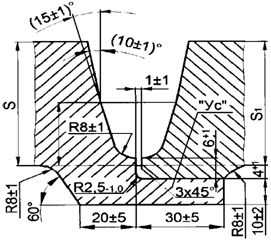

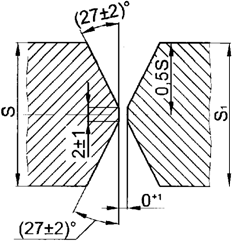

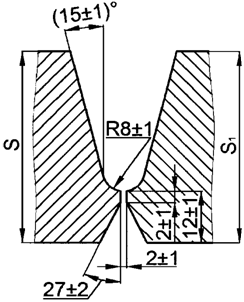

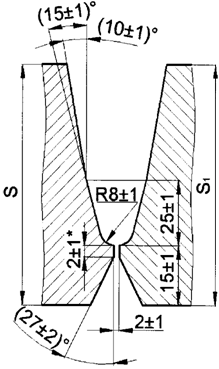

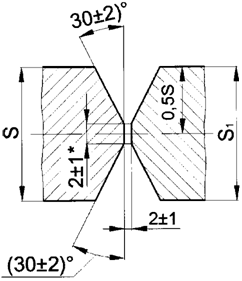

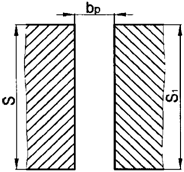

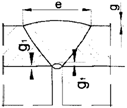

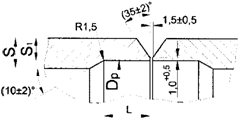

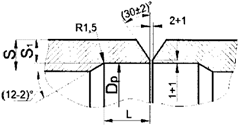

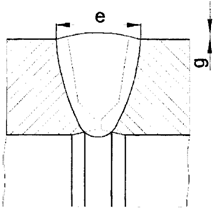

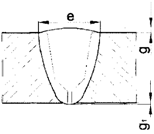

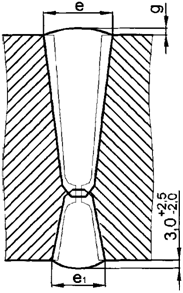

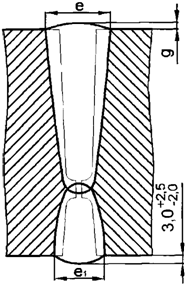

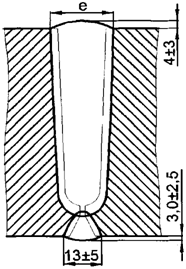

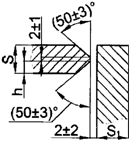

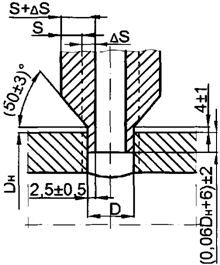

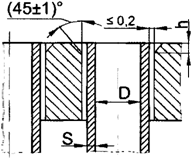

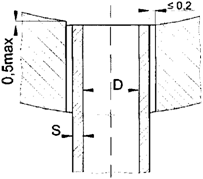

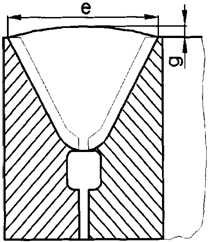

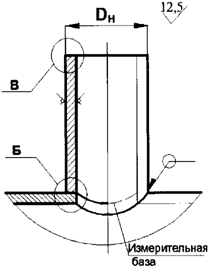

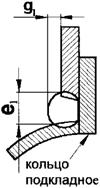

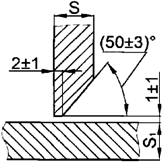

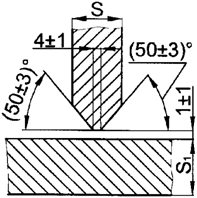

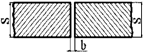

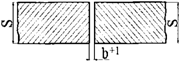

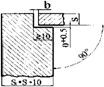

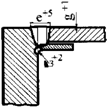

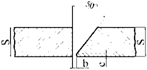

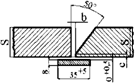

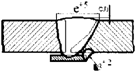

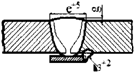

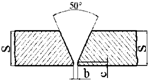

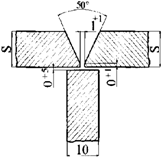

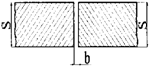

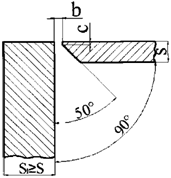

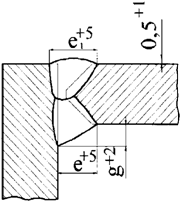

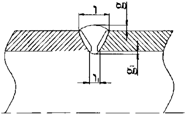

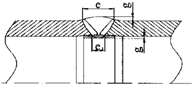

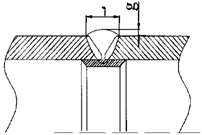

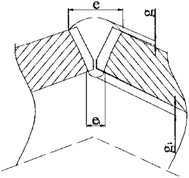

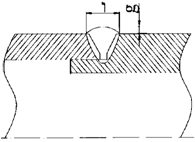

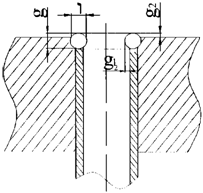

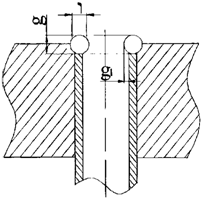

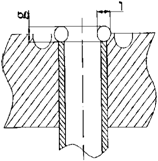

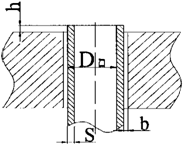

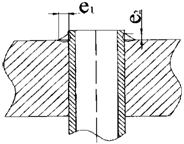

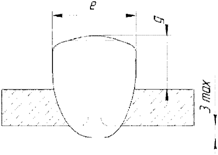

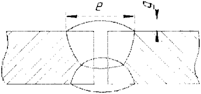

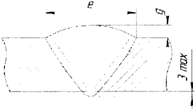

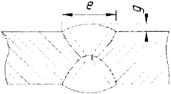

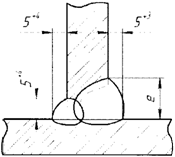

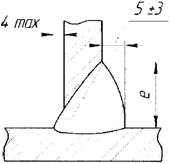

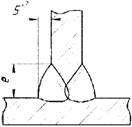

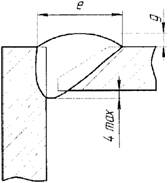

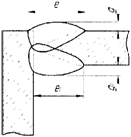

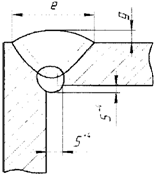

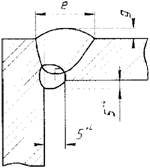

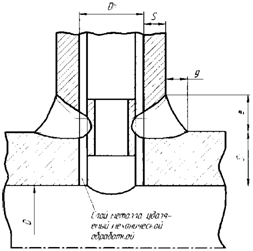

153. One-sided welded joints not accessible for welding from the side of the cladding layer shall be carried out without removing the cladding layer with prior surfacing of edges according to figures 2 and 3.

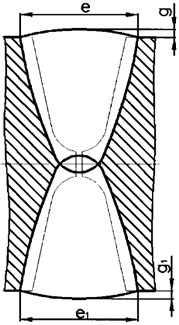

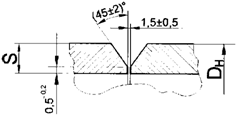

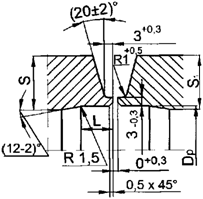

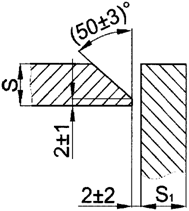

Figure 2. Arrangement of performance of prior

surfacing of parts of two-layered steels

with a cladding layer containing no niobium:

1 - carbon or silica-manganese steel;

2 - cladding layer;

3 - uniform surfacing;

4 - alloyed steel;

5 - double surfacing

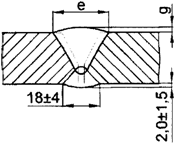

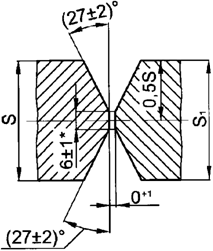

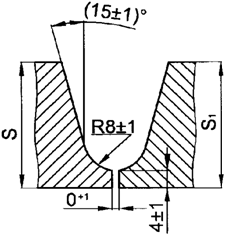

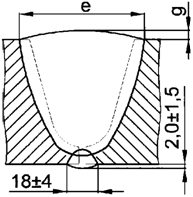

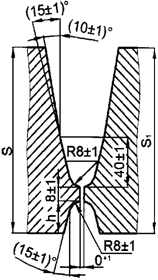

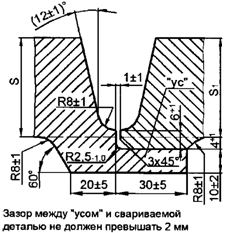

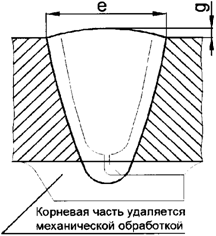

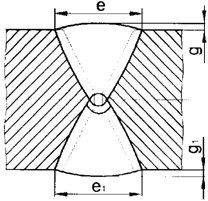

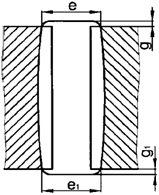

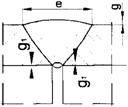

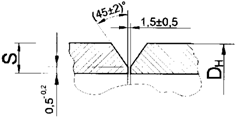

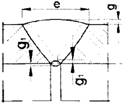

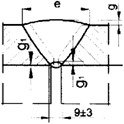

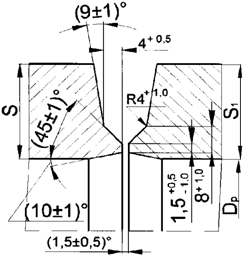

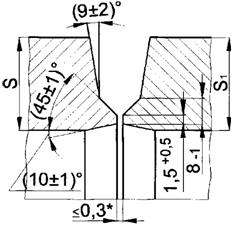

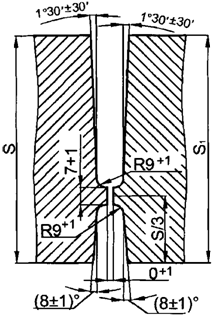

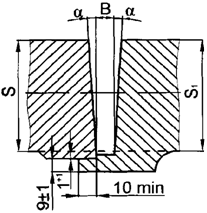

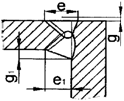

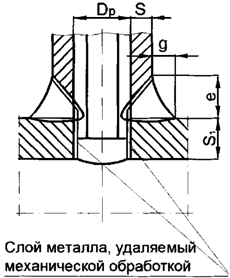

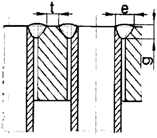

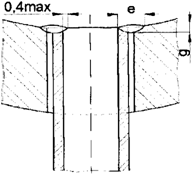

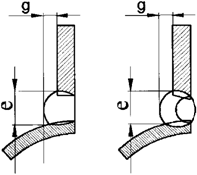

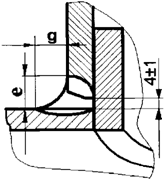

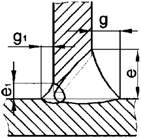

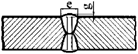

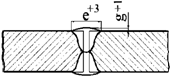

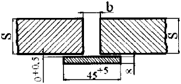

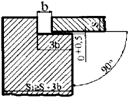

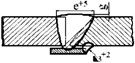

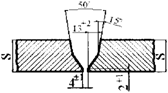

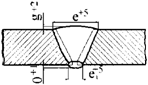

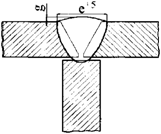

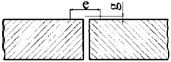

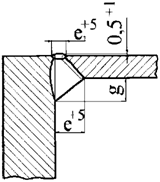

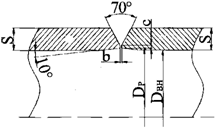

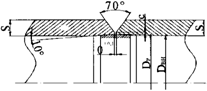

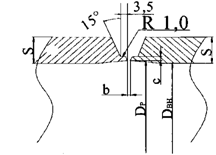

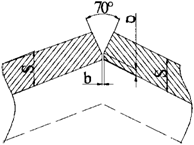

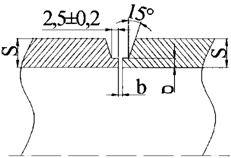

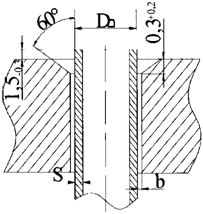

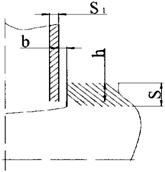

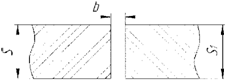

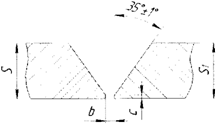

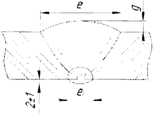

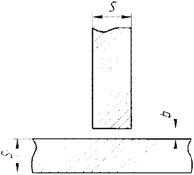

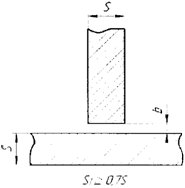

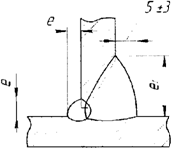

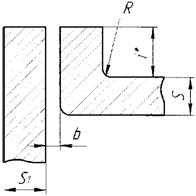

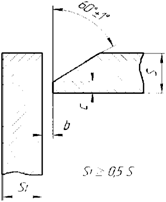

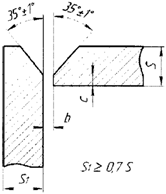

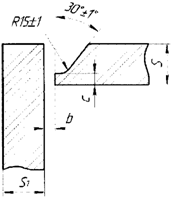

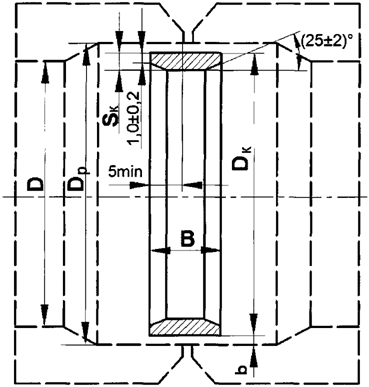

Figure 3. Arrangement of performance of prior

surfacing of parts of two-layered steels

with a cladding layer containing niobium:

1 - carbon or silica-manganese steel;

2 - cladding layer;

3 - uniform surfacing;

4 - separating bead;

5 - alloyed steel;

6 - double surfacing;

If the metal of the cladding layer contains niobium, a separation bead must be made (figure 3), excluding direct contact of the cladding layer with the metal of the prior surfacing on the edges. The separation bead must be made with coated electrodes of grades TsL-25/1 or ZIO-8 or the welding wire of grade Sv-07Kh25N13 (for argon arc welding).

The thickness of the first layer and (or) the total thickness of the prior surfacing should correspond to the same parameters used for welding of steel parts of different structural classes.

154. After prior surfacing heat treatment shall be performed of parts in the area of surfacing (if any), as well as subsequent machining.

155. Welding of parts with surfaced edges should be performed with welding materials as per table No. 2.4 N of appendix No. 2 to these Rules.

156. At welding of parts of two-layer steels with parts of pearlitic steels, the cladding layer shall be removed, after which the welded joint shall be made with welding materials intended for welding parts of steel of the corresponding grades, with the restoration or without subsequent restoration of the cladding layer.

157. At welding of parts of two-layer steels with parts of high-chromium steels, the removal shall be carried out of the cladding layer, after which the welded joint shall be made with welding materials intended for welding parts of steel of the corresponding grades, and the subsequent surfacing of the cladding layer.

158. At welding of parts of two-layer steels with parts made of austenitic steels, the edges of parts of two-layer steels shall be subjected to prior surfacing, and then making the weld joint.

159. Welding to the cladding layer of parts of two-layer steels, protective shirts, as well as parts that are not loaded with pressure, should be performed without removing the cladding layer where they overlap the fillet welds, if the design height of the fillet weld does not exceed 8.0 mm. In this case, the cladding layer shall be considered as austenitic steel.

Electroslag welding

160. Parts made of silicon-manganese and alloy steels, as well as high-chromium steels should be supplied to electroslag welding after complete heat treatment (normalization or quenching followed by tempering). Before the beginning of electroslag welding of parts of two-layer steel, some of the cladding layer shall be removed on the width sufficient for installation of water-cooled sliders and plates.

161. Electroslag welding of a welded joint shall be carried out without interruption.

In the event of a forced break, the welding must continue after removal of the weld area with a shrink hole. Removal of the specified section of the seam when welding parts of alloy steels shall be carried out after the prior tempering of the made part of the welded joint.

At welding of parts made of austenitic steels in the case of the removal of the seam section with a shrink hole after performance of the welded joint, austenization shall be required to be held.

162. At performance of welded joints with ring seams of parts made of steels of pearlitic class, after welding 1/3 of the perimeter of the joint, the initial portion of the seam shall be removed with oxy-acetylene, mechanical or plasma cutting or air-arc gouging. The temperature of the metal in the zone of oxygen-acetylene or plasma cutting or air-arc gouging of welded joints of alloy steel parts should not be lower than 200 °C. The cut edges and the adjacent seam surfaces and the base metal should be cleaned of burrs and scale.

Argon arc welding

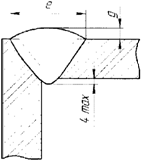

163. At welding pipes and other cylindrical parts of austenitic steels, high-chromium steels and iron-nickel alloys, the reverse side of the welded seam must be protected during the performance of the first two layers by blowing the shielding gas.

To reduce gas consumption, it is allowed to install removable plugs in the welded parts to create a chamber of the required volume. Protection of the root of the seam is provided by passing gas through the chamber in a volume equal to 4 - 5 times the volume of the chamber before welding, and then blowing gas during the performance of the first two layers of the seam.

Welding of aluminum alloy parts

164. The following methods of welding in a shielding gas environment are used to perform welded joints:

a) manual welding with non-consumable electrode with filler material (including compressed arc);

b) automatic welding with non-consumable electrode with filler material (including compressed arc);

c) automatic welding with consumable electrode (including pulsed arc welding);

d) semi-automatic welding with consumable electrode (including pulsed arc welding);

It is allowed to use two or more welding methods to perform a single welded joint (combined welding).

165. Manual welding with a non-consumable electrode must be performed with alternating current. In the case of compressed arc welding with water-cooled electrodes, welding must be carried out at reverse polarity direct current.

166. Automatic welding with a non-consumable electrode must be carried out on assembly and welding stands with a forming pad.

167. Semi-automatic and automatic welding with a consumable electrode must be carried out with direct current of reverse polarity.

168. At an air temperature below 0 °C, the welding work in the installation conditions must be carried out with drying of the welded edges at a width of 50.0 - 60.0 mm from the seam axis by electric heating or by heating with the flame of a gas burner to 100 - 120 °C.

The heating temperature of the edges must be controlled with a contact thermoelectric, infrared or laser thermometer (pyrometer).

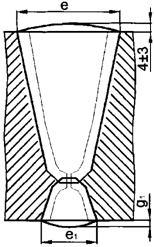

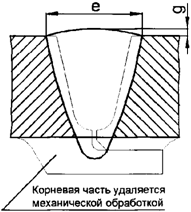

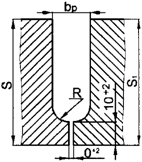

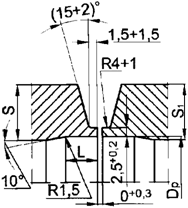

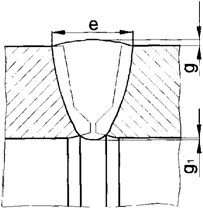

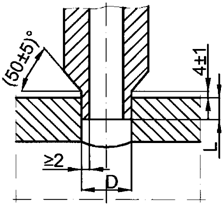

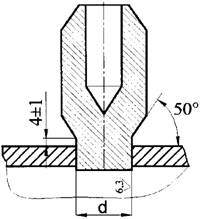

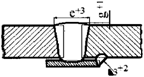

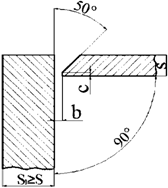

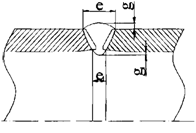

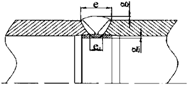

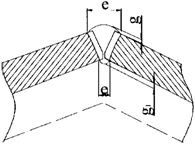

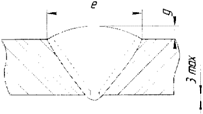

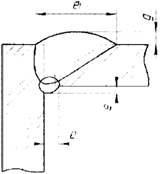

169. T-joints, for which requirements are imposed to the depth of penetration, and butt joints should be performed in a two-sided seam.

Before applying the seam on the reverse side, the root of the seam of the first pass to the pure metal must be removed mechanically to form a groove. The opening angle of the groove edges should be 60+10°, and the radius of curvature of its bottom - not less than 3.0 mm. The roughness of the groove surface should not exceed Ra 10 microns (Rz 40 microns). The use of abrasive tools or liquid coolant shall not be allowed.

170. Welding of butt joints shall be performed in a one-sided seam according to one of the following options:

a) on a removable pad of austenitic steel or copper with a groove for the formation of the root of the seam; the shape and size of the groove shall be established by process documentation;

b) in the cases stipulated by engineering documentation, the remaining pad made of aluminum or its alloys of the same grade as one of the welded parts shall be used;

c) without fixture, with back forming of seam;

d) with formation of a bulge from the side of the root part, its height exceeding the values established in Appendix N 5 to these Rules, with backup welding without filler wire.

171. When performing T-joints with structural incomplete penetration, the value of the non-penetration shall be determined by the amount of root face of the edge of the welded element.

172. When performing T-joints with single-or double-sided dressing of edges, the first pass must be performed with the provision of penetration and removal of the root of the seam mechanically, and the following one - with aiming alternately at the leg and the wall, to ensure the required size and shape of the seam.

173. The beginning and the end of the seam must be performed on service plates of aluminum alloys. The thickness of the plates, their shape and dimensions shall be specified in the process documentation. In case of an allowance of not less than 50.0 mm along the length of the edges to be welded, welding shall be carried out without service plates. In the absence of service plates, the end of the seam must be brought to the previously performed section of the seam, with the crater to be filled.

174. At double-sided welding of pipes the root pass must first be welded from the inside (backup seam).

175. Depending on the size of pipes, structural elements of edge preparation, welding method, shielding gas and ambient temperature, non-cooled, cooled and heated removable pads shall be used.

It is allowed to use a fixture for assembly and calibration of joints of pipes for welding as a pad.