Переводы документов / Translations in English

Описание

Скачайте приложение

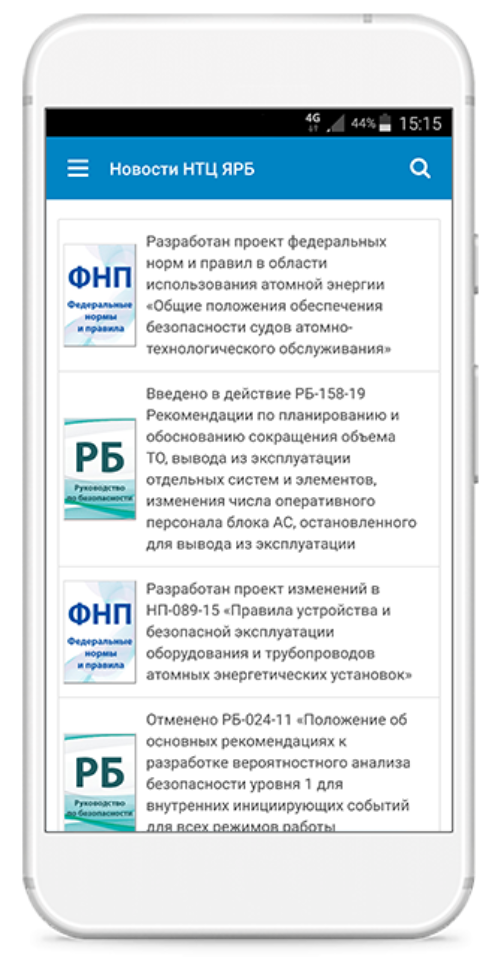

Документы Ростехнадзора, новости об изменениях в законодательстве - всегда у вас под рукой.

Просто наведите камеру телефона на QR-код

Скачайте приложение

Документы Ростехнадзора, новости об изменениях в законодательстве - всегда у вас под рукой.